Purging compounds are specialty chemical compounds used to purge or clean color pigments, additives, and resins from extrusion or injection molding equipment. They help remove any remaining material inside the machine that may damage future production runs or affect the quality of the final products. Purging compounds find widespread applications in industries like automotive, packaging, electrical & electronics and construction.

The Purging Compound Market is estimated to be valued at US$ 596.5 Mn or Mn in 2023 and is expected to exhibit a CAGR of 5.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

Purging Compound Market is primarily driven by growing demand from automotive and packaging industries. The global automotive production has been increasing steadily which requires efficient purging of equipment during transitions. Similarly, the packaging industry utilizes purging compounds extensively to switch between different resin and color batches during production of parts and components. Another major driver is the transition towards operation optimization and quality control across manufacturing sectors. Purging compounds help minimize downtime and production loss while delivering consistent quality, thereby boosting their demand. Stringent regulations around reuse and processing of industrial waste is also propelling the Purging Compound Market growth.

Segment Analysis

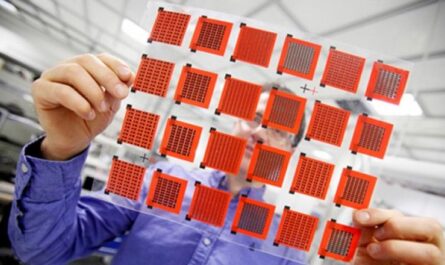

The purging compound market is segmented into liquid purging compounds and solid purging compounds. The solid purging compounds segment currently dominates the market and accounts for over 65% share. Solid purging compounds such as PAEK and polyethylene have greater thermal resistance and better compatibility with engineering thermoplastics owing to which they are widely used for purging of machines between product changeovers and color changes.

PEST Analysis

Political: There are no significant political risks affecting the purging compound market.

Economic: The purging compound market is driven by the global plastic and polymer processing industry which is expected to grow steadily. Additionally, increasing construction and automotive production especially in Asia Pacific will augment the demand for engineered plastics and indirectly boost market growth.

Social: Rising demand for purging compounds from consumer product packaging, appliances, and electronic goods industries indicates growing social acceptance of plastics.

Technological: Continuous product innovations by major players such as development of new purging compounds with better efficiency and customized solutions for different applications will support the market expansion.

Key Takeaways

The global purging compound market is expected to witness high growth, exhibiting CAGR of 5.6% over the forecast period 2023 to 2030, due to increasing plastic production globally. The market size is estimated to reach US$ 856.7 Mn by 2030. Regionally, Asia Pacific dominates currently accounting for over 40% share due to massive growth in plastic processing capacities especially in China, India, Japan and South Korea. Rapid urbanization and growing consumption of consumer goods will augment the regional market during the forecast period.

Key players operating in the purging compound market are Asahi Kasei Corporation, Clariant A.G., CALSAK Corporation, Daicel Corporation, DowDuPont Inc., Formosa Plastics Corporation, Kuraray Co., Ltd., Chem-Trend L.P., Polyplast Muller GmbH, and Claude Bamberger Molding Compounds Corporation. Key players are focusing on new product development strategies by extensive R&D to strengthen their market position. For instance, Asahi Kasei launched new series of optimized purging compounds suitable for medical and 3C applications in 2020.