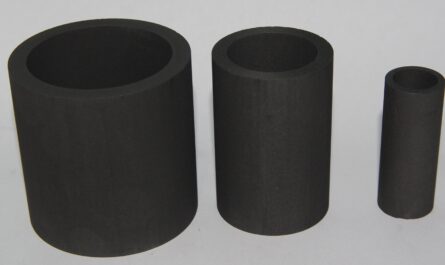

The high alumina aggregate industry stands as a beacon of innovation and resilience, reaching new heights in response to the evolving needs of various sectors. As a critical component of refractory materials, high alumina aggregates play a pivotal role in high-temperature applications across industries such as steelmaking, cement production, and glass manufacturing.

At the core of the High Alumina Aggregate industry lies a commitment to excellence in performance, reliability, and sustainability. High alumina aggregates, composed primarily of alumina and other refractory minerals, exhibit exceptional properties such as high melting points, thermal shock resistance, and chemical inertness, making them indispensable in environments with extreme temperatures and harsh conditions. As industries continue to push the boundaries of performance and efficiency, the demand for high-quality high alumina aggregates remains strong, propelling the industry to unprecedented heights.

One of the driving forces behind the ascent of the high alumina aggregate industry is the growing demand for refractory materials in emerging markets and industries. Rapid industrialization, urbanization, and infrastructural development in regions such as Asia-Pacific, Latin America, and the Middle East are fueling demand for steel, cement, and glass products, driving the need for high-performance refractories like high alumina aggregates. Additionally, emerging sectors such as renewable energy, aerospace, and electronics manufacturing are creating new opportunities for high alumina aggregates, further contributing to the industry’s growth trajectory.

Moreover, advancements in manufacturing technologies and production processes are reshaping the landscape of the High Alumina Aggregate industry, enabling manufacturers to produce high-quality aggregates with superior properties and performance characteristics. Innovations such as rotary kiln calcination, granulation, and advanced quality control systems allow for precise control over particle size distribution, mineral composition, and microstructure, resulting in high alumina aggregates optimized for specific applications and performance requirements. Additionally, investments in research and development are driving the development of novel formulations and compositions of high alumina aggregates, expanding their applications and market potential.

Furthermore, sustainability and environmental considerations are increasingly shaping the high alumina aggregate industry, driving efforts to reduce energy consumption, minimize emissions, and optimize resource utilization. High alumina aggregates offer inherent advantages in terms of energy efficiency and environmental sustainability, making them a preferred choice for industries seeking to minimize their carbon footprint and environmental impact. As regulations become more stringent and industries prioritize sustainability, the demand for eco-friendly refractory materials like high alumina aggregates is expected to continue growing.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it